• Dual Cross-Over Technology: Our Dual Cross-Over Relief Valve with Makeup Check employs advanced technology to provide seamless pressure regulation and prevent excessive pressure build-up.

• Makeup Check Feature: The integrated makeup check feature allows for automatic replenishment of hydraulic fluid, minimizing downtime and enhancing system efficiency.

• Wide Pressure Range: Available in various pressure ratings, our relief valve accommodates diverse system requirements, ensuring versatility and adaptability.

• High Flow Capacity: Engineered to handle high flow rates, this valve is ideal for applications requiring efficient and consistent pressure control.

• Quick Response Time: With its dual cross-over design and makeup check functionality, our relief valve exhibits rapid response times, maintaining precise pressure control even in dynamic operating conditions.

• Pressure Drops: HDI manufactured cartridge valves including the Dual Cross over relief valves has been designed to minimize pressure drops improve system efficiency

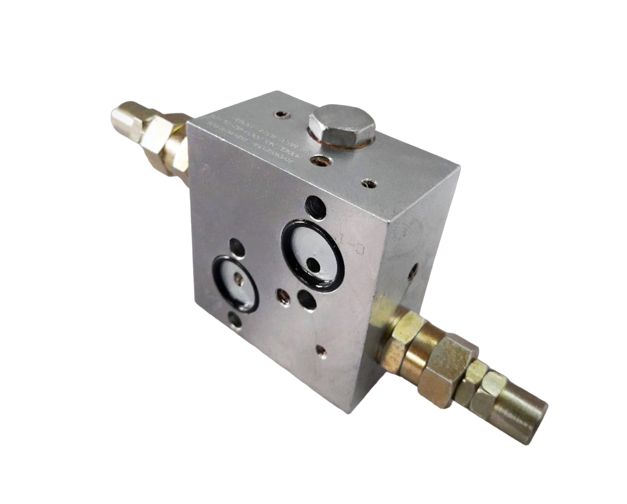

Dual Cross Over Relief Valve with Makeup Check

Dual Cross-Over Relief Valve with Makeup Check: Ensuring Precise Pressure Regulation and Enhanced System Efficiency

HydroDyne Industries is a trusted manufacturer of high-quality Dual Cross-Over Relief Valves with Makeup Check. Our innovative valve combines the benefits of dual cross-over technology with a makeup check feature, offering superior pressure regulation and increased system efficiency. Designed for demanding industrial applications, this valve ensures smooth operation, preventing pressure spikes, and maintaining optimal pressure levels.

Product Specifications: Dual Cross Over Relief Valve with Makeup Check (XRDD-MUC Series)

• Type: Dual Cross-Over Relief Valve with Makeup Check

• Flow Range: 0-150LPM

• Operating Pressure Range: 10Bar -315Bar

• Max Pressure Rating: 350Bar

• Valve Body: Aluminium Alloy,MS,cast iron-GG40

• Mounting Style: Cartridge,Inline Body

• End Connections: BSP 3/8”, ½”, ¾”, 1”

• Operating Temperature: Max Temperature:-110°C

• Media Compatibility: Mineral based or synthetic hydraulic oils with lubricating properties

• Set Pressure Adjustment: Setting Screw & Lock nut

• Seal Type: Nitrile,Viton

• Quality Assurance: Each valve undergoes rigorous testing and inspection to ensure reliable performance and quality.

• Custom Solutions: Customizable relief valve designs available to meet specific application requirements.

1. Mobile Equipment: This valve is extensively used in mobile equipment, including construction machinery, agricultural vehicles, and material handling equipment. It ensures safe and efficient hydraulic performance in demanding applications.

2. Industrial Machinery: The valve finds applications in industrial machines such as presses, injection molding machines, and metal forming equipment. It provides optimal pressure control, enhancing productivity and safety.

3. Automotive Industry: Dual Cross-Over Relief Valve with Makeup Check is employed in automotive hydraulic systems, such as power steering and braking systems, ensuring smooth and controlled operation.

4. Material Handling: It plays a vital role in material handling equipment like forklifts and cranes, providing reliable pressure regulation during lifting and lowering operations.

5. Energy Sector: The valve is used in hydraulic systems in power plants and renewable energy facilities, contributing to stable and reliable energy production.

6. Aerospace and Defence: Dual Cross-Over Relief Valves with Makeup Check find applications in aerospace and Defence industries, protecting critical hydraulic systems in aircraft and military equipment.

7. Construction Equipment: This valve is widely utilized in construction equipment, such as excavators and loaders, protecting hydraulic systems from pressure spikes and ensuring safe operation.

8. Marine Applications: In marine equipment, such as hydraulic steering systems and winches, the valve offers precise pressure control for efficient and safe maritime operations.

9. Material Processing: Dual Cross-Over Relief Valves with Makeup Check are used in material processing equipment, such as crushers and conveyors, to optimize process efficiency and system reliability.

10. Power Generation: The valve is employed in hydraulic systems within power plants, ensuring stable and efficient operation of turbines and generators.

11. Robotics and Automation: In robotics and automated systems, this valve provides accurate pressure regulation, supporting smooth and reliable motion control.

12. Oil and Gas Industry: Dual Cross-Over Relief Valves with Makeup Check are utilized in the oil and gas industry for various applications, including wellhead control and hydraulic systems.

13. Custom Applications: The versatility of this valve allows it to be customized for specific and unique requirements in diverse industries, optimizing performance and system efficiency.