**Key Features of Multi Passage Hydraulic Rotary Union :**

• High Passage Capacity: With up to 24 passages, our hydraulic rotary union handles a wide range of media simultaneously, optimizing system efficiency.

• Low Friction Design: The hydraulic rotary joint incorporates precision bearings and seals, ensuring minimal friction and extending the service life of the joint.

• Leak-Proof Performance: Each passage is carefully sealed to prevent cross-contamination and leakage, ensuring reliable and safe fluid transfer.

• Durable Construction: Made from high-quality materials, our hydraulic rotary union withstands the rigors of heavy-duty applications, providing long-lasting performance.

• 360-Degree Continuous Rotation: The swivel joint allows unrestricted rotation, enabling continuous fluid transfer without any interruptions.

• Versatile Mounting Options: The hydraulic rotary union can be custom-configured with various mounting options to suit specific installation requirements.

• Temperature and Pressure Resistant: It operates effectively under a wide range of temperatures and pressures, adapting to diverse working conditions.

• Maintenance-Friendly: The modular design facilitates easy maintenance and replacement of individual passages, minimizing downtime.

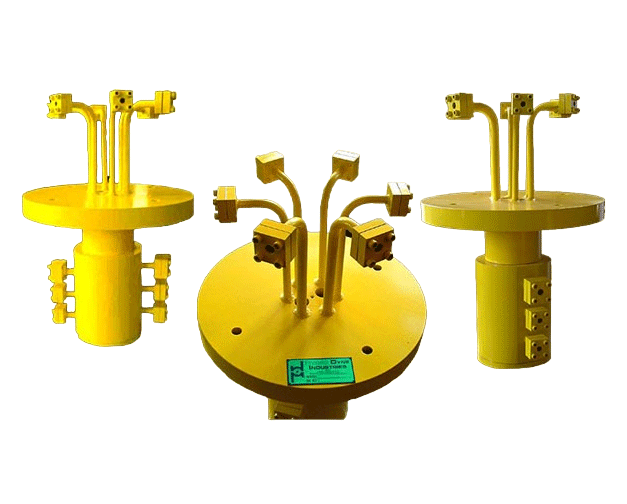

Multi Passage Hydraulic Rotary Union (Upto 24 Passages)

Engineered for the most intricate hydraulic and pneumatic systems, HydroDyne Industries' multi-passage hydraulic rotary unions, manufactured with precision right here in Mumbai, India, stand as a testament to innovative fluid transfer solutions. These advanced hydraulic rotary joints boast the capability of handling multiple fluids simultaneously – hydraulic oils, air, gases, and liquids – through up to 24 dedicated passages. This eliminates the need for a web of individual rotating connections, drastically reducing potential leak points and guaranteeing smooth, uninterrupted fluid flow within your system.

We pride ourselves on being a leading hydraulic rotary union manufacturer in Mumbai,india. Our commitment to quality ensures that each hydraulic rotary union is crafted to meet the highest standards of performance and reliability.

For more information about our hydraulic rotary unions, hydraulic rotary joints, and swivel joints, or to discuss your specific requirements, please contact us. As a leading hydraulic rotary unions manufacturer in Mumbai, India, we are dedicated to providing solutions that meet your needs and exceed your expectations.

• Passage Capacity: Up to 24 passages, allowing simultaneous transfer of various media.

• Media Compatibility: Suitable for hydraulic fluids, air, gases, and liquids.

• Maximum Operating Pressure: Up-to 250 BAR(customizable based on application requirements).

• Temperature Range: Capable of operating within -40°C to 205°C.

• Rotation Speed: 1000 RPM (customizable based on application requirements).

• Bearing Type: Precision bearings,Brass and composite material bushes

• Sealing: Each passage is equipped with reliable seals to prevent leakage and cross-contamination.

• Materials: High-quality materials, such as steel, stainless steel and aluminum.

• Mounting Options: Customizable mounting configurations to suit specific installation needs.

• Maintenance: Modular design allows easy maintenance and replacement of individual passages.

• Size and Weight: Compact and lightweight design for space-saving and easy handling.

1. Rotary Index Tables: Our multi-passage hydraulic rotary unions are commonly used in rotary index tables of manufacturing machinery. They facilitate the seamless transfer of hydraulic fluids and other media, ensuring smooth and precise rotation in automated production processes.

2. Roll Mills: In steel and paper industries, hydraulic rotary joints are applied in roll mills for cooling and lubrication. They enable efficient fluid transfer, contributing to the optimal performance and extended lifespan of rolling equipment.

3. Printing Presses: Printing presses rely on our rotary joints to supply ink and cooling fluids during the printing process. The uninterrupted fluid transfer ensures consistent print quality and prevents ink drying.

4. Automated Packaging Machines: Multi-passage hydraulic rotary unions are essential components in automated packaging machines that require continuous fluid supply for various functions like sealing, cutting, and labeling.

5. Marine Loading Arms: In marine applications, our hydraulic rotary joints serve as vital components in loading arms and hoses for fluid transfer between vessels and terminals, supporting safe and efficient loading and unloading operations.

6. Offshore Drilling Equipment: The multi-passage swivel joints are used in offshore drilling equipment to deliver hydraulic power and control various functions, enhancing the productivity and safety of drilling operations.

7 Rotary Swivels: Construction and mining equipment utilize our hydraulic rotary unions as rotary swivels, enabling hydraulic and pneumatic connections while allowing unrestricted rotation for smooth machine movements.

8. Hydraulic and Pneumatic Systems in Defence: Our rotary unions play a crucial role in various defense applications, including hydraulic and pneumatic systems in military vehicles, aircraft, and marine vessels.

9. Automotive Testing Equipment: In automotive testing facilities, hydraulic rotary joints are utilized in test rigs to deliver hydraulic power and control various automotive components' movements for testing and validation purposes.

10 CNC Machines: CNC machines benefit from our multi-passage hydraulic rotary joints to supply hydraulic or pneumatic power to multiple toolheads, ensuring precise machining operations.

11 Fluid Transfer in Renewable Energy Applications: In renewable energy systems like wind turbines and solar tracking systems, our hydraulic rotary unions enable efficient fluid transfer, contributing to the optimal performance of these green energy technologies.