• Bidirectional Flow: The Shuttle Valve's unique design allows bidirectional flow switching, ensuring fluid can flow from either input to output based on the pressure differential between the two circuits.

• Seamless Changeover: With its rapid response, the Shuttle Valve swiftly switches between hydraulic circuits, minimizing downtime and ensuring continuous operation.

• Compact and Space-Saving: Our Shuttle Valves are designed to have a compact footprint, making them suitable for installations with space constraints.

• Durable Construction: Crafted from robust materials, our Shuttle Valves are built to withstand challenging conditions, offering long-lasting performance and reliability.

• Quality Assurance: We prioritize quality, and each Shuttle valve undergoes rigorous testing and inspection to meet industry standards and deliver consistent performance.

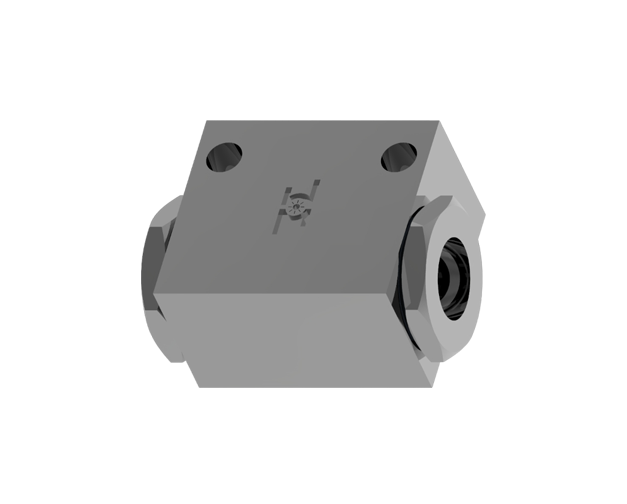

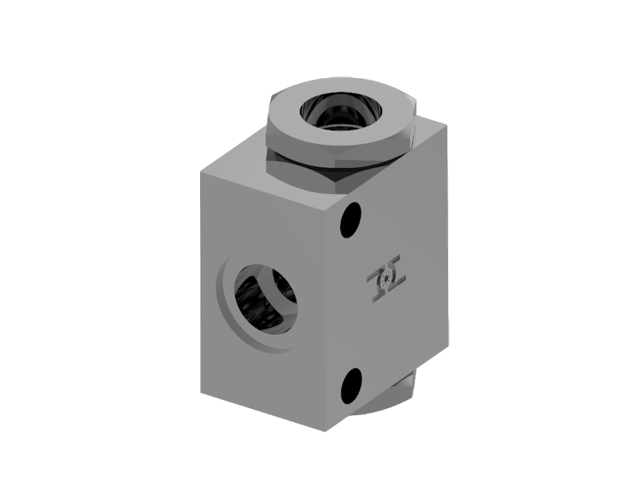

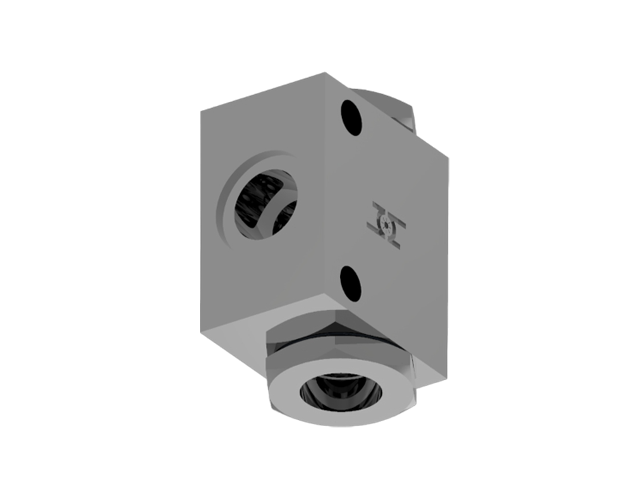

Shuttle Valve

Shuttle Valve: Seamless Flow Switching for Hydraulic Systems

Hydrodyne Industries is a trusted Manufacturer of high-quality Shuttle Valves engineered to deliver smooth flow switching and enhance the efficiency of hydraulic systems. The Shuttle Valve, also known as a changeover valve or double-check valve, is a versatile component that allows seamless switching between two hydraulic circuits. With its innovative design, this valve enables the prioritization of fluid flow from one circuit to another, making it a vital element for applications requiring rapid and precise fluid control.

Product Specifications: Shuttle Valve (SC Series)

• Type: Shuttle Valve

• Flow Range: 0-75 LPM

• Operating Pressure Range: 0Bar -245Bar

• Max Pressure Rating: 350Bar

• Valve Body: Aluminium Alloy,MS,cast iron-GG40

Mounting Style: Cartridge,Inline Body

• End Connections: BSP 3/8”, ½”, ¾”

• Operating Temperature: Max Temperature:-110°C

• Media Compatibility: Mineral based or synthetic hydraulic oils with lubricating properties

• Seal Type: Nitrile,Viton

• Quality Assurance: Each valve undergoes rigorous testing and inspection to ensure reliable performance and quality.

1. Mobile Hydraulics: In mobile hydraulic systems, such as construction equipment and agricultural machinery, Shuttle Valves enable seamless switching between different hydraulic functions, optimizing equipment performance and productivity.

2. Material Handling Equipment: Shuttle Valves are essential in material handling machinery, including forklifts and cranes, allowing efficient switching between lifting and rotational functions during material transport.

3. Aerospace and Aviation: These shuttle valves play a critical role in aerospace and aviation applications, ensuring fluid control between different hydraulic systems in aircraft and ground support equipment.

4. Marine and Offshore: Shuttle Valves find applications in marine and offshore equipment, facilitating seamless switching between hydraulic circuits in winches, cranes, and propulsion systems.

5.Industrial Automation: In industrial automation processes, Shuttle Valves control fluid flow between multiple actuators, enabling synchronized and efficient movements in robotic systems and manufacturing processes.

6. Oil and Gas Industry: Shuttle Valves are employed in the oil and gas sector for applications like wellhead control and hydraulic power units, facilitating fluid switching in critical operations.

7. Power Generation: In power generation plants, Shuttle Valves assist in fluid switching between different hydraulic systems, contributing to efficient energy production and plant operation.

8. Automotive Systems: Shuttle Valves are utilized in automotive hydraulic systems, including braking and suspension systems, ensuring smooth fluid flow transitions for enhanced vehicle performance and safety.

9. Medical Equipment: These shuttle valves are integrated into medical equipment, such as patient lifters and hospital beds, to enable smooth and reliable fluid control for patient care.

10. Manufacturing Machinery: Shuttle Valves find applications in manufacturing machinery, such as injection molding machines and metalworking equipment, optimizing fluid control for precise operations.

11. Food and Beverage Industry: In the food and beverage sector, Shuttle Valves ensure efficient switching between different processing functions, contributing to streamlined production and packaging processes.

12. Construction and Mining Equipment: Shuttle Valves are used in construction and mining equipment to control fluid flow during various hydraulic functions, enhancing equipment reliability and performance.

13. Renewable Energy Systems: In renewable energy applications like wind turbines and solar trackers, Shuttle Valves enable efficient switching between hydraulic circuits, contributing to optimal energy capture and utilization.

14. Transportation and Logistics: These shuttle valves find applications in transportation and logistics equipment, such as truck-mounted cranes and loading ramps, ensuring seamless fluid control during cargo handling tasks.

15. Waste Management: Shuttle Valves are employed in waste management equipment, such as compactor trucks and waste handling systems, optimizing fluid flow during waste collection and disposal processes.